CD & DVD Colour Printing Industry Set to Two bottle.

by:TURNKEY

2020-06-26

According to InfoTrends, a place research and strategic consulting firm for the digital imaging and document solutions industry, gross billings from 'colour print on demand' systems used by the CD and DVD duplication industry, topped USD$1.9 billion worldwide in 2009. Forex trading is projected to roughly double to near $4 billion by 2014.

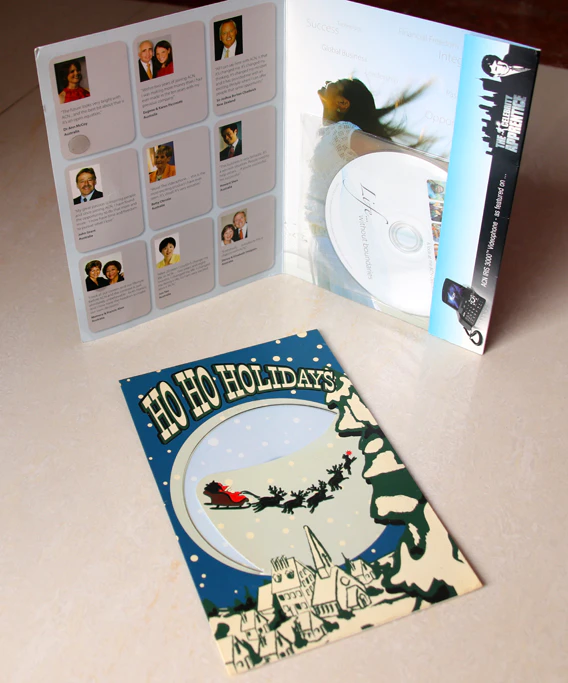

DVD and CD print jobs that once took several days to complete, can now be drained the same day and the client signed off proof is identical to the final printed product. Improvements your technology have transformed disc packaging, CD and DVD print design and the chance to to rapidly change patterns.

There is no doubt that Digital Printing, for smaller runs of CD, DVD and paper parts, is the only technique go when full colour images are required. There are several different CD disc printing options available, including thermal retransfer, inkjet, broadband 6 colour UV curable digital inkjet and the traditional silkscreen and offset print methods. Each technology possesses its own strengths and weaknesses.

Thermal retransfer has a far lower capital entry level and can be operated by a relatively unskilled workforce, however the ribbon is expensive per print and a special, expensive, receptive surface has to become applied to the vertebrae.

Inkjet disc printing is relatively cheap and easy to performance. While the resolution is reasonable, it is often washed-out due to the use of special highly matt inkjet receptive surfaces on the optical your media. There are inkjet receptive glossy based discs and UV-cured lacquer overcoats, however both options significantly increase the cost per disc.

Offset printing has good resolution, but being a 4 colour process is actually difficult to match PMS colours, commonly used in corporate logos. The devices are capitally intensive, the printing plates are expensive, require time to produce, and usually require client signed-off proofs. The cost per print, after initial setup, is very low and stable and no special surfaces are required on the DVD information. CD media can present some challenges, such as 'surface peel', depending on the media and brand of printer manual. At the commencement of the print job there is significant loss of discs which requires the job to overrun.

Similarly, silkscreen printing equipment is sometimes costly. While it has lower resolution than offset printing, it does have PMS colour matching. The cost per print is low, the print stable and no special surfaces will need be applied towards the DVD media early. Similar to offset printing, there exists a significant associated with rejected prints at print start up while the various colour images are aligned.

Without a doubt, for any larger scale CD or DVD replication or duplication, UV cured digital printers should be thought about. Whilst the capital outlay is significant, they offer 6 colour printing, low initial setup cost (no screens or plates), require no over production to balance print colours or align screens and they can print directly onto uncoated, inexpensive, white-coated discs. There isn't an contact with the media during paper process, which significant for recordable media and Blu-ray discs.

Whilst the inks are inexpensive by using a cost per piece similar to offset printing irrespective for this print quantity, skilled labour is found it necessary to maintain the items.

Digital print technology reduces lead times, eliminates surplus inventory, overruns, plate and screen creation and reduces the need for high res digital proofs.

One of verified of digital optical media printing is it allows which print variable data easily, such as sequential or incremental serial numbers, barcodes, and personalized disks. As pressure grows to be greener, more cost efficient, and turn things around quickly, digital printing is a great solution for your growing market of short run solutions.

Custom message